Cryostar partners with Vahterus to Transforms Truck-Fuelling Stations

Founded in 1972, Cryostar specialises in designing and manufacturing cryogenic equipment. The company offers turbomachines, gas heaters and vaporisers, pumps, turbines as well as compressors for industrial gas, energy and hydrocarbon applications. In the twenty-first century, the company has extended its range to process plants in the fields of natural gas and clean energy.

Cryostar employs 500 people at its headquarters in Hesingue, France, in the centre of the three-border region constituting France, Germany and Switzerland. 90% of the company’s production is exported. During almost five decades in operation, Cryostar has developed an international network through distributors and agents in Italy, Spain, Japan, Korea, India, South America, alongside its own branches that employ 100 people in the UK, Singapore, China, Brazil and the US.

Cryostar has been involved in LNG applications for several decades. In the year 2000, the company was one of the pioneers developing truck-fuelling stations. Two kinds of truck technologies co-exist and they require different pressures and temperatures in the reservoir. Initially, the standard fuelling stations included a device to heat and saturate LNG in the storage tank.

As a technological leader, Cryostar saw an opportunity to change this. The company decided to develop an ‘on the fly’ saturation system that would warm the LNG on demand when fuelling the truck.

Compared to the old technology, the two main advantages of this solution are the ability to:

– deliver low temperature LNG to trucks that support it, and therefore increase their autonomy and avoid any possible

vent of their storage tank

– keep cold LNG in the storage tank and reduce or avoid the need to cool it down, which requires plenty of energy. This

creates significant energy saving, leading to an optimised environmental aspect.

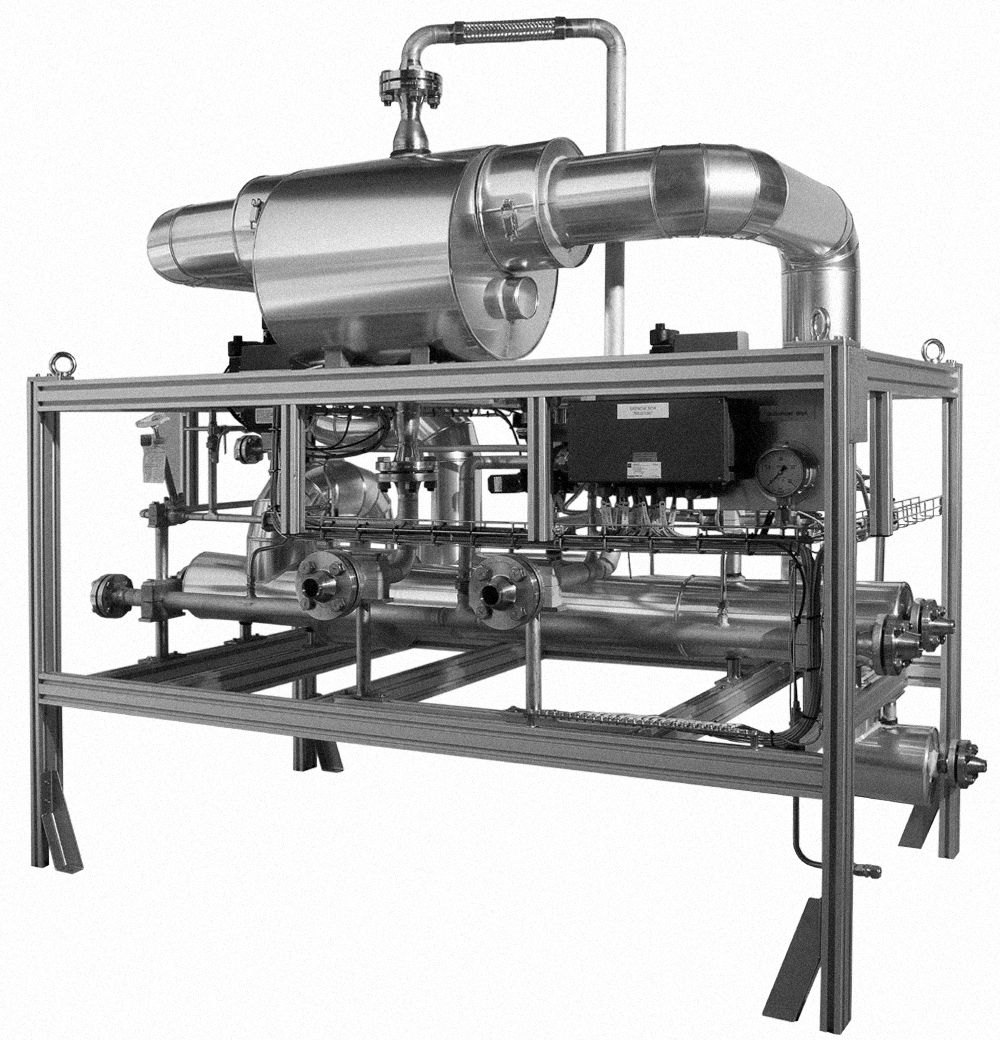

In order to perform quick cooling down and avoid heat ingress into the system, Cryostar was looking for a compact and high-efficiency cryogenic heat exchanger. At Cryostar, selecting suppliers is a key activity, where purchasing, QHSE and engineering teams work together on an evaluation matrix. In this case, Vahterus was selected as a partner mainly for its product’s technology, design and calculation capacity.

Cryostar was able to adjust its process so that it resulted in optimised size and heating capacity of the heat exchanger. An engineering expert from Cryostar participated in a class at Vahterus premises in Finland, and was then able to make all calculations on his own. The two companies exchanged 3D models, which were compatible, and by the time the first heat exchanger was shipped, no support from Vahterus was needed for installation.

Today, Cryostar is convinced it made the right choice when selecting Vahterus as a partner. The company has been able to deliver saturation system units to Canada, Australia and Europe and more recently has qualified the design for Shell.

Because of the challenging operating conditions, the Vahterus heat exchanger is a good solution for Cryostar’s system. Besides being compact in size, its fully welded structure eliminates the need for a gasket that could easily break in such a low operating temperature.

The first Vahterus heat exchanger was installed in 2013 and is still in operation, alongside roughly 60 further Vahterus units in Cryostar’s systems today. This kind of long-term cooperation is extremely valuable for Vahterus, deepening the understanding of how the market, and possible applications for heat exchangers, are evolving.

Experts at Cryostar consider LNG the perfect transition fuel between oil and the future mix of greener sources of energy. When used as a fuel, LNG or CNG reduces CO2 emissions; it drastically decreases particle emissions and is less noisy than diesel-driven engines. Moreover, it allows an easy transition to bio-LNG, a completely CO2 neutral fuel.

LNG can be used for replacing LPG and oil in industrial applications, diesel for road trucks, gasoline and diesel for personal cars, heavy fuel oil or other fuels for ships, as well as any other energy source for power generation.

In the future, more and more of our built environment will be powered by renewable sources of energy such as solar, wind, hydrogen, biofuels and biogas. However, there are still major issues to be solved – for example, energy storing and learning to use different sources of renewable energies for different applications.

Until the new technologies have become established, LNG helps to fill the gap by continuing to supply different applications while slowly reducing the footprint on the environment and enabling an easy transition to biogas.

Download the case study as a PDF

Transform Your Project with Vahterus Expertise

Eager to bring innovation to your heating project? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective, sustainable and energy-efficient heating solutions.

Discover more of our Customer Stories

40 MW Ammonia Heat Pumps are Revolutionising District Heating in Sweden

E.ON, one of the world’s largest investor-owned electric utility service providers, installed four GEA heat pumps, each with a heating capacity of...

Colonial Pipeline Runs Between the Gulf Coast and the New York Harbor Area

Colonial Pipeline, headquartered in Alpharetta, Georgia, is the largest US refined products pipeline system and can carry more than three million barrels...

CO2 Cold Store Operates with Energy Efficiency and Sustainability in Eastern China

Yonghai Yi, Senior Sales Engineer at Vahterus China ...