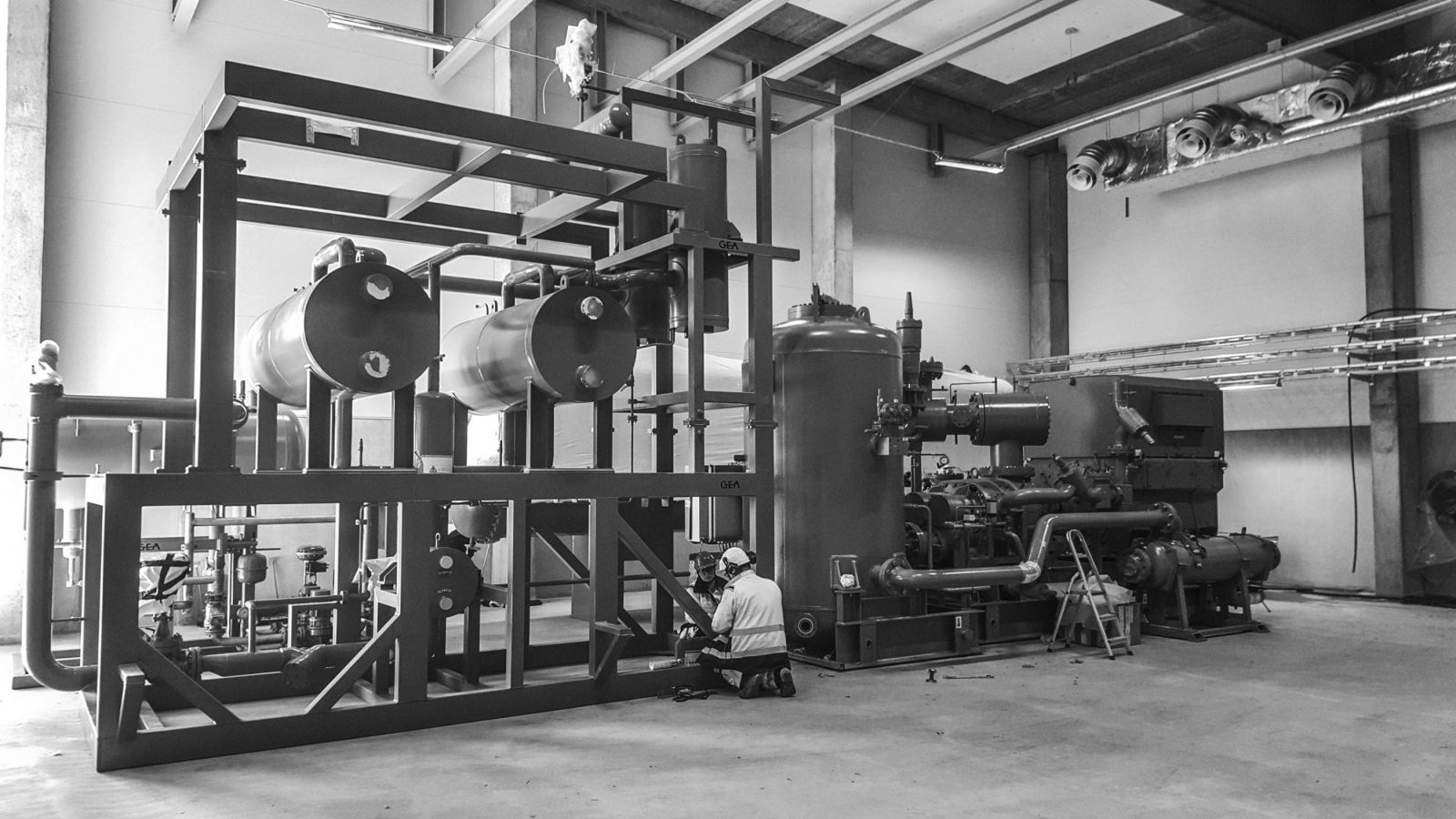

40 MW Ammonia Heat Pumps are Revolutionising District Heating in Sweden

E.ON, one of the world’s largest investor-owned electric utility service providers, installed four GEA heat pumps, each with a heating capacity of 10 MW (1 MW = approx. 2,500 homes) next to the sewage treatment and waste incinerator plant in Malmö’s harbour area. The heat-pump system draws nearly 30 MW of heat from the sewage water. Previously sent directly to the sea as waste heat, the energy is now harvested from the clean wastewater before it is returned to the sea. On average, the wastewater is chilled from 14 °C to 8 °C and the energy harvested is used to fuel the district’s heating network through the heat pumps. 40 MW of heat is being returned every second to the district heating network at around 66 °C, providing heat for a total of 10,000 homes.

Energy harvesting

By harvesting the heat from the wastewater, which has a constant high temperature, the plant is running with greater efficiency than if it had been using seawater (-15% efficiency) or ground source water (-10% efficiency).

In the winter, the seawater around Malmö gets close to 0 °C and requires frost protection and a higher temperature lift from the heat pumps. Since there can be some organic material in the wastewater, the Shell & Tube evaporators have been fitted with a ball cleaning system that continuously cleans the stainless-steel tubes to avoid fouling in the heat exchanger and maintain high efficiency without having to stop the heat pump.

District heating network

The heat pump has been integrated into the district heating network to work together with the nearby waste incinerator plant. The water from the city returns to the waste incinerator plant at around 50 °C, whose flue gas economiser is heated to around 55 °C before going into the heat pump, where it is heated to 66 °C. The water then returns to the waste incinerator plant, where it is heated to the temperature required by the heating network, which can vary from 70 °C to 90 °C. The heat pump is designed for delivering heat up to 80 °C, but will rarely deliver above 71 °C.

Refrigerants

To maximise efficiency, ammonia has been chosen as the refrigerant in the heat pumps. This natural refrigerant has a GWP of 0. The plant’s life expectancy is 20–30 years, so it is important to choose a refrigerant that will be available throughout this time span. Many new synthetic refrigerants are being introduced onto the market under the common group name HFO, but as is the case with all the synthetic refrigerants before them, their long-term impact on the environment is unknown and they are likely to be phased out of the market in time. The new refrigerants have also proved to be very expensive: in this case the refrigerant charge would have cost close to £1M, while the ammonia charge cost £20,000.

Economic benefits

The four heat pumps operate in parallel, each with a coefficient of performance (COP) above 3.50, so that each 1 kWh of electricity used by the pump produces 3.5 kWh heat for the city. The pumps will all run at 100% from October to April. In the summer months, there is sufficient heat from other renewable sources to feed into the heating network. Only at peak times in the summer months will one or two of the heat pumps be running. The pumps will deliver 200 GWh per year – 8% of Malmö’s heating demand. This will save 50,000 tons of CO2 emission, the equivalent of taking 10,000 petrol cars off the roads.

Download the case study as a PDF

Transform Your Project with Vahterus Expertise

Eager to bring innovation to your heating project? Our team of experts are ready to collaborate with you. Contact us today to embark on a journey towards cost-effective, sustainable heating solutions.

Discover more of our Customer Stories

Award-Winning Heat Pumps

In 2017, Vahterus UK embarked on an innovative journey with Star Renewable Energy for the iconic Queens Quay heat network project...

GEA Partners with Vahterus for District Heating in Gateshead

GEA has secured the order to deliver the UK’s largest capacity heat pump for district heating. 6 MW of heating energy...

Vahterus Technology Transforms London's Underground Heat

The project to extract waste heat from an underground train network is the first of its kind in the world, and...